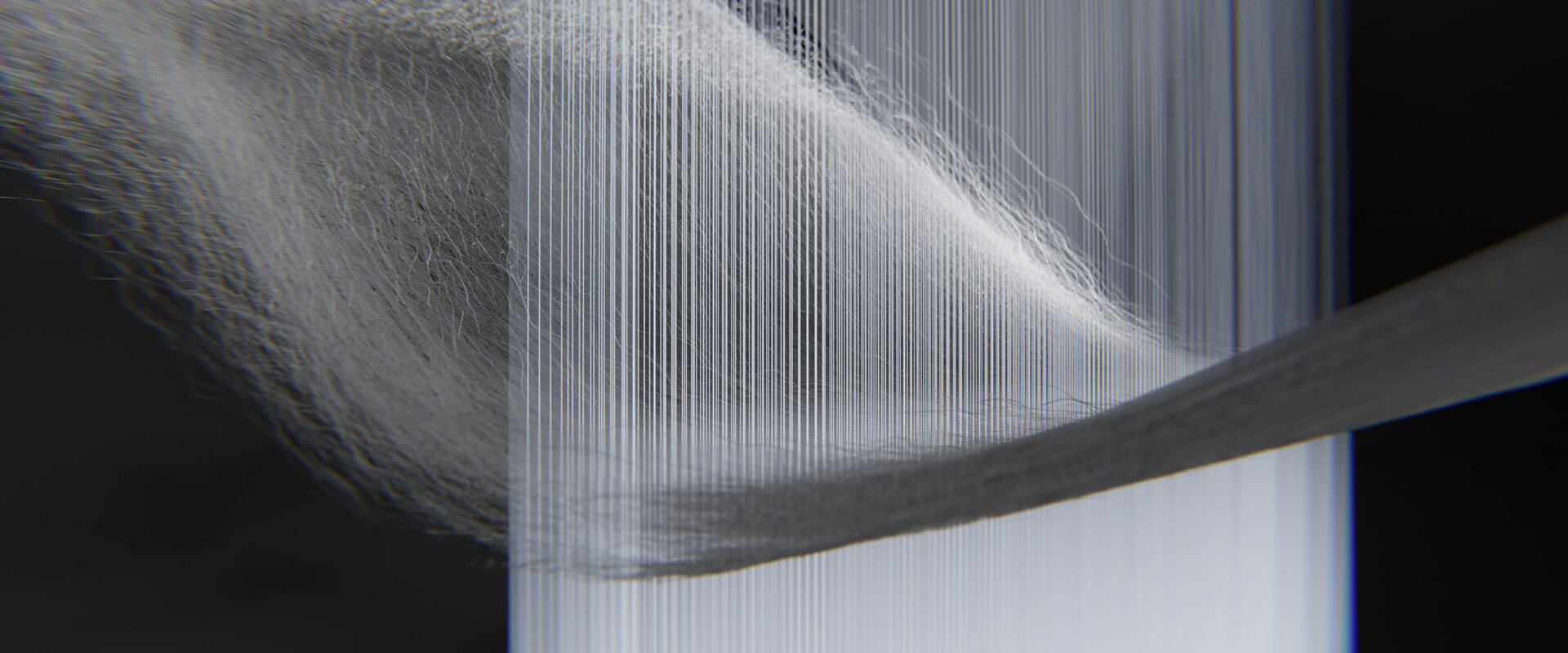

Making of Spunlace Nonwovens: Innovation by Hydroentanglement

Spunlacing, also known as hydroentanglement or water-needling, has established itself as one of the most well-known and innovation-driven technologies for the production of nonwovens. Nonwovens for hygiene applications benefit from the fact that the spunlace process does without binding agents, making spunlace nonwovens particularly environmentally friendly and versatile. But what are the advantages of spunlace technology, and for which nonwoven fabrics is the process used?

The Advantages of Spunlace

Spunlacing offers a number of advantages that set it apart from other nonwoven technologies. Some of its biggest plusses are the softness and drapability of the resulting materials. Doing without chemical bonding agents, spunlace nonwovens are very gentle on the skin. Wipes and personal hygiene products benefit from the high absorbency that also comes with spunlacing. To summarize the advantages of spunlace nonwoven fabrics:

- strength and flexibility

- softness and drape

- absorbency, breathability and pleasant feel

- versatile use in many fields such as construction, household, hygiene, and medical

Spunlace for wipes

Spunlacing is the technology of choice when it comes to nonwovens for wipes as it results in particularly soft yet strong fabrics for use in the household but also in industrial environments. Spunlace nonwoven fabrics from Sandler provide for an optimal combination of absorbency and durability.

The option of optical and tactile structuring through embossing and perforation is another advantage of the spunlace process. These techniques not only enhance the functionality of the wipes – for example, by optimizing dirt absorption or improving tear control – but also enable individual designs that specifically support brand impact and product experience. Additionally, the technology allows for the combination of various fibers to produce, for instance, biodegradable or particularly durable products.

Spunlace for hygiene items

Spunlace nonwovens play a crucial role also in the production of personal hygiene items such as incontinence protection products, feminine care items, or baby diapers. Their superb softness and the skin friendliness render them ideal for sensitive skin. Typically, spunlace nonwovens display a very uniform bond, making products featuring spunlace fabrics delicately soft yet strong.

Spunlacing: an efficient technology for high-quality and versatile nonwovens

Spunlacing is a crucial nonwoven technology, offering a number of advantages for the production of wipes and hygiene products. Spunlacing results in strong and skin-friendly materials for use in many industries. The combination of high quality and versatility makes Sandler spunlace nonwovens a preferred choice for manufacturers of a variety of goods.

Wipes in everyday life

Whether for household use, disinfection, or travel, wipes have become an indispensable part of daily life. Learn more about Sandler nonwovens - in particular Sandler nonwovens for wipes - and what makes them special.