Nonwovens for Hygiene Applications: Function that feels safe

Hygiene products place the highest demands on materials and processing. Nonwovens used in hygiene products have to function reliably and be comfortable on the skin while meeting sustainability requirements. Sandler nonwovens for hygiene feature exactly this combination of high-performance, skin friendliness, and efficient processability for use in care, cleaning, and medical filtration applications.

Protection provided by Hygienic Nonwoven Solutions

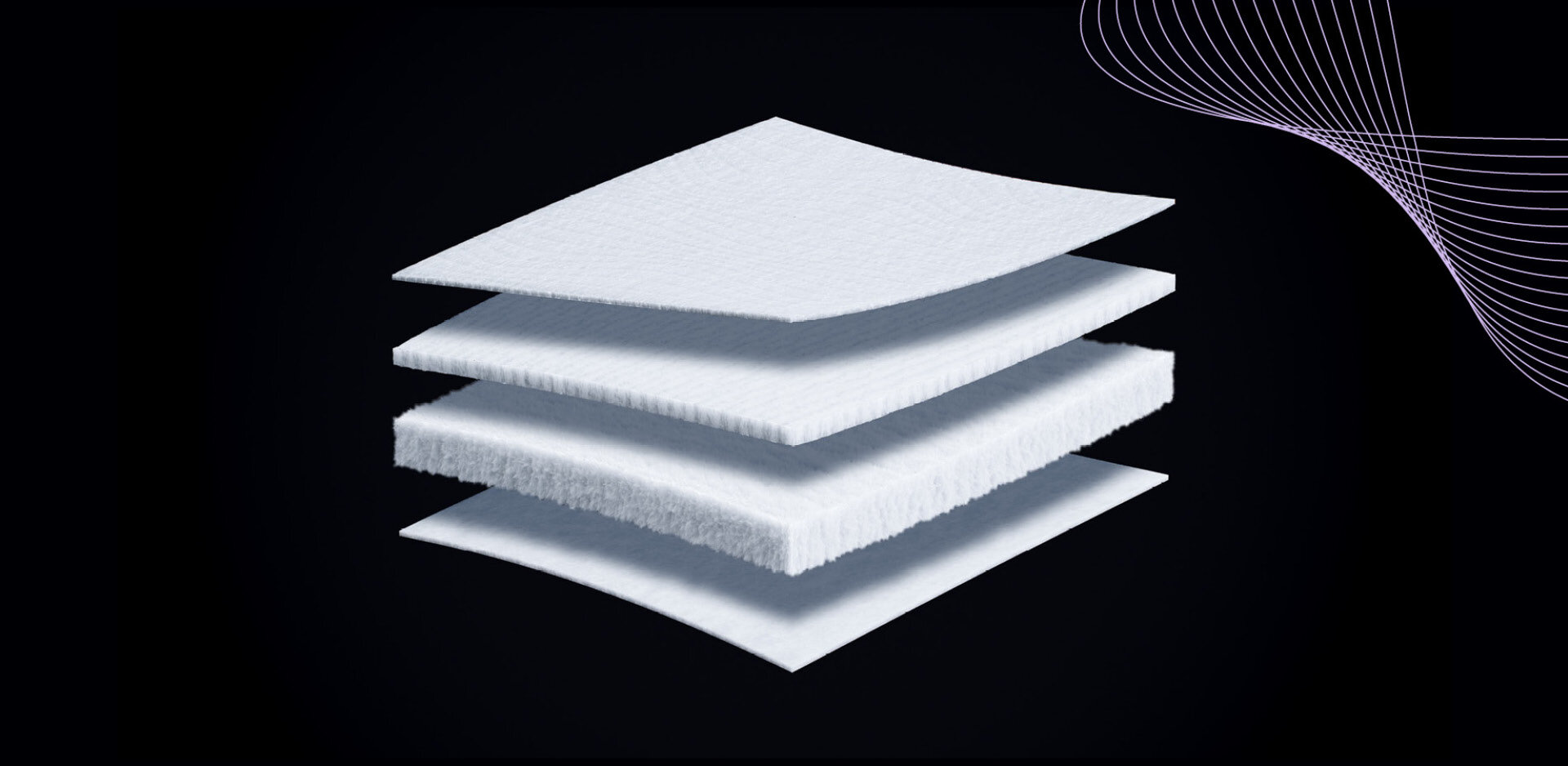

The skin of young and old comes into direct contact with our nonwoven fabric in many hygiene products. Therefore, is has to be gentle, effective and safe. Sandler Group develops nonwovens for distribution layers, top sheet and back sheet applications, elastic closure systems as well as outer covers. Depending on the application, they transport fluids in a targeted manner or reliably retain them.

Hygienic nonwovens are also used in the medical sector for disinfectant wipes, bandages, compresses, and temporary supports, combining stability and skin compatibility. Our water-permeable nonwoven fabrics let fluids pass through in a controlled manner, ensuring a safe and comfortable feel.

Cleaning made easy with high-performing Wipes

Sandler nonwoven substrates have long been essential for wipes used in baby care, cosmetics, and households. Our nonwovens are soft, tear-resistant, and highly absorbent, making them ideal for sensitive skin on one hand and repeated use in household applications on the other.

Single-use products are still commonly used in the hygiene industry. Focusing on sustainability, Sandler Group works to manufacture wipe substrates from alternative, biologically degradable fibers. These substrates offer high performance and reduce the material usage to the essentials, opening up new possibilities for creating sustainable hygiene products.

Ensuring Hygiene with Filtration Nonwovens

Filtration plays an essential role in hygiene, particularly in medical applications. Sandler Group supplies filter layers for surgical masks and filtering face piece respirators (FFR). Additionally, Sandler produces inner layers for masks and tape nonwovens that provide high comfort and breathability.

layerlab: Our Modular System for Customized Hygiene Products

With layerlab, Sandler has created a development platform that makes it easier for manufacturers to develop new hygiene products. The modular system allows for the quick combination of different nonwoven layers, e.g. topsheets, distribution layers, and backsheets. It also makes material properties comparable.

There are three design classes to choose from:

- Standard: economical and functional

- Premium: Soft and comfort-oriented

- Sustainable: resource-saving and material-efficient

layerlab speeds up development processes, reduces testing, and supports sustainable product design. This transforms Sandler Group from a materials supplier to an innovation partner for the hygiene industry.

Nonwovens for Hygiene Applications: Quality that Protects

For decades, Sandler Group has developed high-performance nonwovens that deliver outstanding results in a vast range of hygiene applications. Whether the application is for protection, cleaning, or filtration – Sandler hygiene nonwovens combine functionality, skin-friendliness, and sustainability – for products that feel safe.