Needlepunch: tried and tested since 1965, still cutting edge

Sandler Group utilizes the needlepunch process in the manufacture of nonwovens since 1965. Being the company's oldest production method, mechanical bonding by needling has made a significant contribution to the company's success. To this day, this technology continues to impress with its versatility and plays a central role in numerous industries worldwide.

Versatile, resilient, proven

Whether for acoustic or thermal insulation, filtering, padding or protecting - needled nonwovens fulfill crucial functions in many areas of life and work. It is used in the construction, household, industrial and mobility sectors, among others. Here, needle punched nonwovens not only score with their high strength, but also with their wear resistance. This makes them the ideal solution wherever nonwoven products are subjected to permanent stress.

What is Needlepunch?

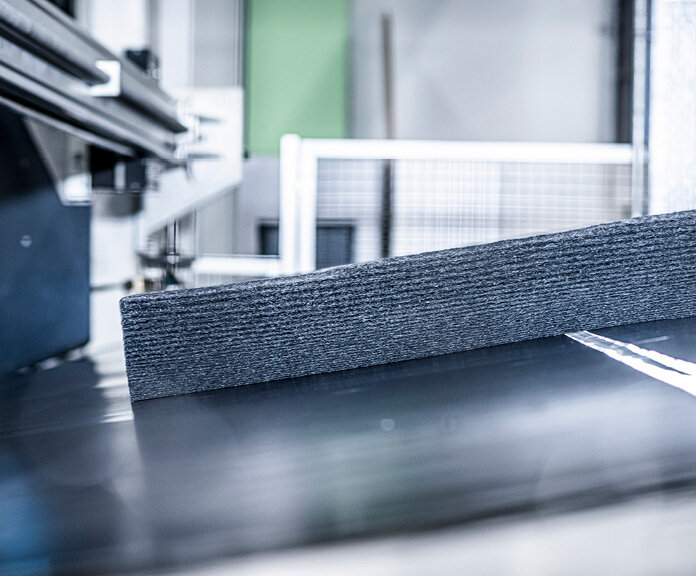

The needlepunch process describes mechanical bonding by needling. This creates nonwovens of different thicknesses and densities, which can be used in a variety of ways. With the needlepunching principle, needles with barbs penetrate a batt of fibers and intertwine the fibers. The result is a resilient, dimensionally stable needled nonwoven.

Sandler Group relies on modern process technology for the mechanical bonding in order to process the web precisely to match the requirements of the respective application.

Advantages of needle punched nonwovens

Needlepunch nonwoven is characterized by a number of technical and functional advantages:

- Exceptional wear resistance: the mechanical entanglement ensures high tenacity and dimensional stability.

- Maximum flexibility: Different needle stitch densities, types and speeds enable individual solutions that are precisely tailored to the respective application.

- High durability: Thanks to their structure, needlepunch nonwovens retain their functionality even with long-term use.

The future of Needlepunch

Needlepunching has been a tried and tested technology representing progress through experience at Sandler since 1965. It will continue to be a key technology in the nonwovens sector in the future, above all because the flexible mechanical process of needlepunching enables precise control of the material properties - an advantage that Sandler Group has consistently used for decades to develop sustainable products. Read more details about the process.